Warehouse Intralogistics Solutions Integrated Systems & Warehouse Solutions You Can Depend On

Get More Our of Your Warehouse with Advanced Intralogistics

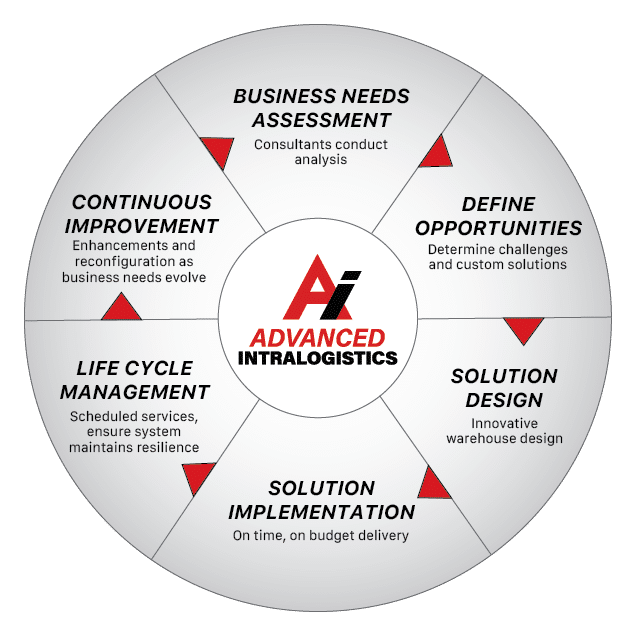

Advanced Intralogistics, a member of the Shoppa’s family of businesses, is our full-service systems integration partner that provides expert automation and engineering for all warehouse intralogistics solution needs. With innovative technology like conveyor systems, robotics, AS/RS, AGVs/AGFs, sortation systems, warehouse consulting and design, and more, we can serve our clients across North America.

System Design & Engineering

Stragetigically engineered, customized systems that address your unique needs and acheive your desired results.

Learn More

Conveyor Systems

Flexible, durable systems for moving a variety of goods, increasing throughput, and generating faster fulfillment.

Learn More

Sortation Systems

Customizable, high-tech solutions for diverting, transferring, and sorting packages throughout the order fulfillment process.

Learn More

Automated Storage & Retrieval Systems (AS/RS)

Sophisticated solutions for efficiently managing a large inventory of stored items.

Learn More

Robotics & AGVs

Innovative solutions for automating routine tasks while minimizing the risk of human error.

Learn More

Integrated Systems

Intelligent, connected systems that minimize your critical warehouse functions to maximize productivity and throughput.

Learn More

Experienced Professionals

Our team is comprised of highly-trained consultants, designers, engineeers, and technicicans who possess many years of combined industry experience.

Integrated Solutions

Using the Toyota intralogistics methodology, we’ll help you align and streamline individual processes so that everything works together, seamlessly.

Best-in-Class Suppliers

We work with the world’s most innovative and trusted brands and can deliver customized solutions tailored to your exact specifications.

Automation

We’ll help you eliminate labor intensive, costly, time-consuming duties by introducing automated solutions.

Let Robots Do the Work

Robotics can streamline every part of your process. From material handling to picking, packing, sorting, and loading. These intelligent machines can also become a critical component of your inventory management by tracking inventory and alerting workers when supplies run low.

TALK WITH OUR TEAM OF EXPERTS AT ADVANCED INTRALOGISTICS.

Integrated Systems and Warehouse Solutions You Can Depend on.