What class of forks do I need for my forklift?

When it comes to operating a forklift efficiently and safely, having the right type of forks is crucial. Forklifts are versatile machines used in various industries to lift and transport heavy loads, and the type of forks you choose can significantly impact the performance and productivity of your forklift.

Understand Your Material Handling Needs

Forklifts are categorized into classes according to different factors such as fuel type and purpose. Fork designs need to adhere to industry norms for interchangeability, regardless of the lift truck maker. However, they are tailored to match the lifting capacity of each individual forklift. The first step in choosing the right lift truck forks is to assess your material handling needs. Consider factors such as the types of loads you handle, the weight and dimensions of the loads, the environment in which the forklift operates, and any specialized requirements unique to your industry. Understanding these needs will help you determine the right length, width, and capacity of the forks required to efficiently handle your materials.

Fork Size and Capacity

Forklifts come in various sizes and configurations, and the fork size and capacity need to match the specifications of the forklift model. Properly sized forks ensure that the load is centered and distributed evenly, preventing tilting or tipping. Forks with inadequate width may result in load slippage, while forks that are too wide might interfere with nearby objects or cause difficulty maneuvering in confined spaces. The length of the forks should be sufficient to support the full length of the load and extend beyond it by at least six inches. Overloading the forklift with loads exceeding its rated capacity can lead to accidents, equipment damage, and injuries to operators and bystanders. On the other hand, using forks with a lower capacity than required may lead to premature wear and failure of the forks under heavy loads. Adhering to the recommended capacity ensures the forklift can handle loads safely and effectively.

Fork Material and Construction

Investing in high-quality forks made from the right materials and constructed with precision will not only ensure the forklift’s optimal performance but also promote a safe and productive material handling environment. There are variations in fork construction, such as standard, forged, and coated forks. Forged forks are more robust and have a higher load-bearing capacity, making them suitable for heavy-duty applications. Coated forks offer better protection against rust and corrosion, making them ideal for outdoor or damp environments. Choose the fork material and construction that aligns with your specific operational conditions and budget.

Safety Features

Safety should be a top priority when selecting lift truck forks. Look for features like heel wear indicators, which provide a visual cue to monitor the wear on the forks’ heels. This helps identify when it’s time for replacement to prevent failure during operation. Additionally, some forks come with safety lock mechanisms to secure them to the forklift carriage, reducing the risk of accidental detachment while lifting loads.

Consider Fork Attachments

Certain applications may require specialized fork attachments to enhance productivity and versatility. Popular attachments include fork positioners, sideshifters, and extensions. Fork positioners allow the operator to adjust the fork spacing without leaving the cab, while sideshifters enable lateral movement for precise load positioning. Fork extensions are useful for handling longer loads that exceed the length of standard forks. Evaluate your operational needs to determine if any of these attachments would be beneficial for your lift truck.

Forklift attachments options include:

• The Side-shifter

• Fork Positioner

• Paper Clamps

• Push/Pull Attachment

• Multiple Pallet Handler

• Classic Fork Extensions

• Rotators

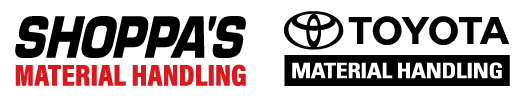

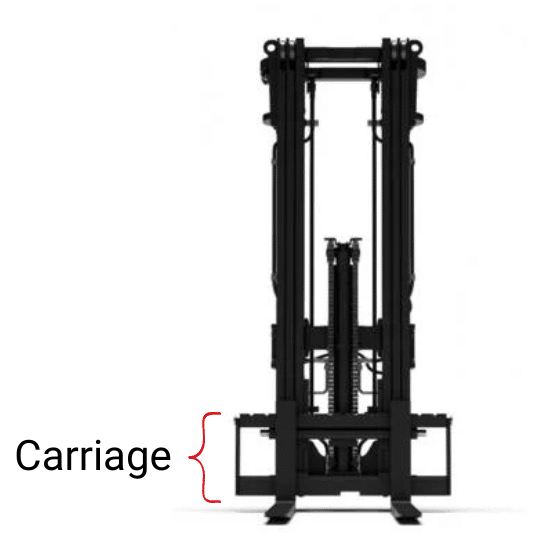

The Key to Calculating What Size Forks You Need:

The way to determine which class of forks you need is to measure how tall your carriage is. The carriage is located on the front of your forklift that the forks connect to.

Need assistance with choosing replacement forks? Our Shoppa’s parts experts are here to help. We offer various options for replacement forks and attachments compatible with most forklift brands.

We’re Here to Help

Choosing the right lift truck forks is crucial to optimize material handling efficiency and maintain a safe working environment. Understanding your material handling needs, considering fork size and capacity, selecting the appropriate material and construction, and prioritizing safety features are all vital aspects of the decision-making process. By making a well-informed choice and investing in high-quality lift truck forks, you can enhance productivity, reduce downtime, and ensure the safety of your operators and materials during every operation. Remember to consult with experts or forklift manufacturers for personalized recommendations based on your specific industry requirements. Contact us today to learn more.