In the complex world of material handling and supply chain operations, any delay, inefficiency, or mistake can have a domino effect throughout the entire system, impacting productivity, customer satisfaction, and ultimately, the bottom line. Recognizing the importance of efficiency, industry leaders such as Toyota have created The Toyota Production System (TPS), which eliminates waste (non-value added tasks) to better streamline processes.

Understanding Visual Management

The Toyota Production System (TPS) is widely regarded as one of the most successful manufacturing systems globally, with lean management at its core. Lean management aims to minimize waste and enhance efficiency in all aspects of the production process. Visual Management, a key component of lean management, utilizes visual tools and cues to communicate information, track progress, and enhance decision-making. This process leverages this advantage to help employees understand processes and situations as quickly as possible. Visual management also quickly identifies bottlenecks, waste, and potential hazards within processes, leading to improved quality and efficiency.

Visual management tools include:

Signs: Signs that are visually displayed are frequently seen in warehouses and serve to indicate potential dangers and necessary actions. The use of various colors and shapes aids in conveying different messages. These signs may include prohibitive, mandatory, warning, and emergency signs.

Boards: Boards are utilized to show locations, chains of command, and processes, providing a clear reference for everyone in the warehouse. Using a simple design and layout these boards are used to display short-term actions. These types of boards are usually found on the factory floor with machine status, daily output metrics, and problem-solving issues for all employees to see.

Posters: Many warehouses post a summary of processes and rules on posters for clarification, so employees can see and review them. Posters can be used to remind people to work safely, company culture, or an event calendar.

Lighting: Lighting can be used to direct machinery traffic or communicate whether an area is safe to enter. Manufacturing facilities use Andon systems to alert supervisors, call maintenance, or even to shut down the line to address an error.

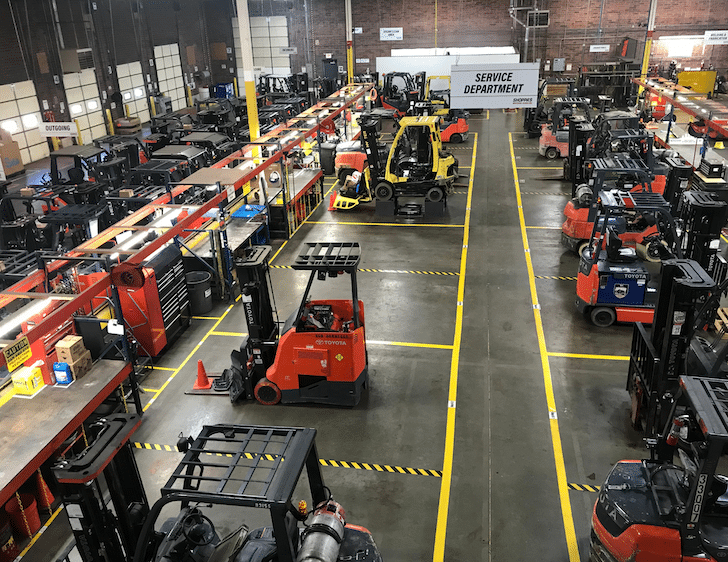

Floor markings: These can indicate dedicated areas, pathways or placement for equipment within a warehouse. An example of this would be marking and labeling locations on the shop floor. Using different colors, you can mark what goes where, and label the places so that the items and tools go to the correct places.

Dedicated spaces: Using tool shadow tape to outline the shapes of particular tools, their presence or absence can be easily identified. This method can also be applied to all equipment, as having a specific location for each item allows for quick assessment of availability and usage status.

Implementing a cohesive visual system throughout a warehouse enables efficient communication of procedures and concepts, ultimately enhancing workflow efficiency and ensuring a secure work environment.

Implementing Visual Management at Shoppa’s

By implementing visual management, we are able to quickly identify issues before they impact our customers. This leads to improved efficiency, quality, and customer satisfaction. We begin this with a comprehensive educational initiative aimed at all levels of the organization. From leadership to frontline employees, understanding the objectives and principles of visual management is paramount to fostering widespread commitment. Soliciting feedback and actively involving team members in the assessment of workplace environments ensures that implementations are tailored to specific needs and challenges.

Shoppa’s employs a systematic approach to introducing visual management tools, prioritizing clarity and effectiveness. Continuous evaluation and refinement are integrated into the operational framework, aligning with the principles of the 5S methodology. By cultivating an organized and visually stimulating work environment, Shoppa’s reduces waste and elevates productivity across its operations.

Beyond efficiency gains, visual management at Shoppa’s serves as a catalyst for standardizing work practices and ensuring consistency. By prominently displaying standard operating procedures and performance metrics, employees are empowered to uphold quality standards and identify opportunities for improvement.

Promoting a Culture of Accountability

Visual management at Shoppa’s fosters a culture of accountability and transparency. By making information readily accessible to all team members, individuals take ownership of their performance and actively contribute to problem-solving and innovation initiatives. Real-time visibility into performance metrics encourages proactive engagement and reinforces a collective commitment to success.

At Shoppa’s, the integration of visual management into material handling and supply chain operations represents a commitment to excellence and continuous improvement. For organizations seeking to optimize their processes and unlock their full potential, Shoppa’s offers tailored Lean Management Consulting services. Contact us today at 866-506-2200 to learn more about how Shoppa’s can elevate your operations through visual management.