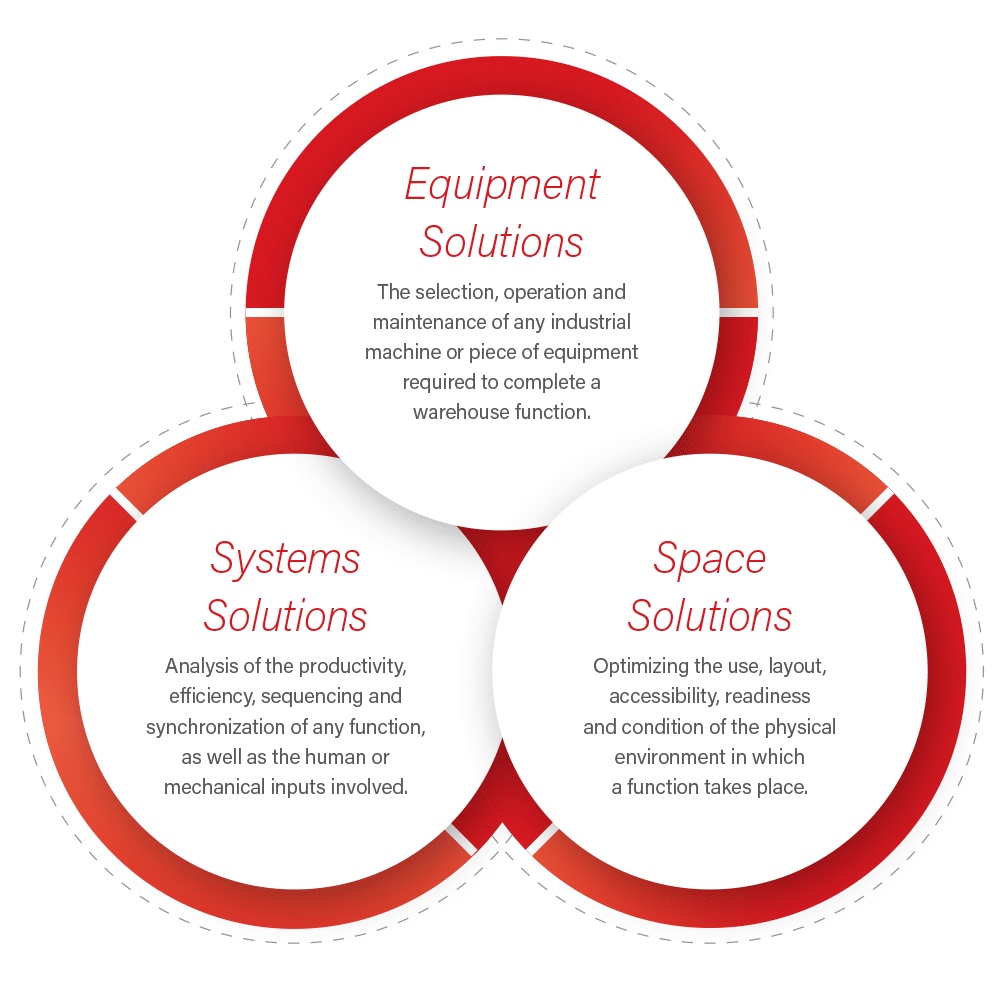

In today’s interconnected warehouse environments, organizations are constantly seeking innovative solutions to overcome complex challenges and achieve optimal productivity. Shoppa’s recognizes this need and has developed a strategic methodology that integrates the three foundational elements that are essential for performing any warehousing or supply chain function: Equipment, Systems, and Space.

The Power of Equipment

The first element of Toyota Intralogistics focuses on the selection, operation, and maintenance of industrial machines and equipment used to complete warehouse or supply chain functions. Shoppa’s understands the critical role that product knowledge and high-quality equipment plays in promoting efficiency and reducing downtime. We undergo extensive product training, and work closely with our suppliers to stay ahead of innovations in warehouse technology. By leveraging our extensive experience and partnership with Toyota, Shoppa’s provides customers with cutting-edge material handling equipment. This ensures the seamless and optimized movement of goods throughout the entire operation.

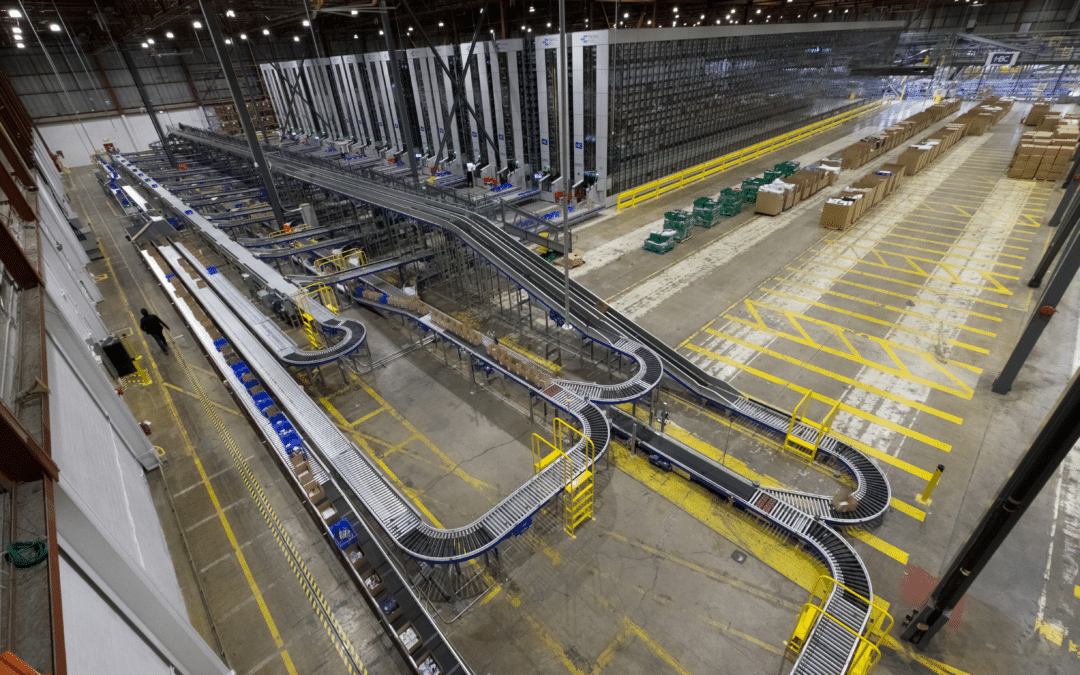

The Importance of Systems

The second element of Toyota Intralogistics delves into the collective actions required to complete warehouse functions. Through strategic analysis of productivity, sequencing, and synchronization, Shoppa’s helps businesses streamline their operations and achieve optimal outcomes with integrated automation systems and warehouse software solutions. Our experts implement and install various systems like conveyor, sortation, robotics, and automated storage and ensures the seamless connection to software and service components. Shoppa’s applies Toyota Lean Management (TLM) principles to existing processes and identify areas for improvement. By utilizing lean management principles, waste is reduced, efficiency is enhanced, and productivity is maximized.

Optimizing Physical Space

The third element of Toyota Intralogistics focuses on the physical environment where warehouse functions take place. Shoppa’s recognizes the significance of layout, accessibility, and condition of the space in determining overall efficiency. Through meticulous planning and design, Shoppa’s helps businesses optimize the use of their physical space. This includes implementing smart storage solutions, maximizing workflow, and futureproofing for growth and expansion. By creating an environment that facilitates seamless operations, businesses can minimize downtime and enhance overall productivity.

The Synergy of Toyota Intralogistics

Toyota Intralogistics seamlessly integrates the three foundational elements to create a comprehensive solution that drives efficiency, promotes sustainability, and enhances customer satisfaction. By considering each element in conjunction with the others, Shoppa’s is able to tailor solutions that address specific challenges and optimize the entire supply chain. Whether it’s automating processes, implementing advanced technologies, or developing innovative strategies, Toyota Intralogistics offers offer complete, turn-key solutions, from consultation and solution architecture, to implementation, support and maintenance.

A Comprehensive Approach

At Shoppa’s, we understand that staying ahead requires innovative solutions that optimize efficiency, promote sustainability, and enhance customer satisfaction. Shoppa’s Toyota Intralogistics offers a comprehensive approach to warehouse operations and supply chain management. To explore how Shoppa’s Toyota Intralogistics can transform your operations, request a consultation or call us at 866-506-2200. Our experts are ready to guide you in creating solutions that make your business run smarter and smoother.