Today, it’s not just time that’s money – it’s space too!

From staffing to technology to product, costs can spiral if you don’t take some key steps to optimize your warehouse. We all know that a well-organized warehouse space cuts down on chaos, encourages productivity and helps your bottom line when your employees and the products they handle work together in ways that make sense. Warehouse management today takes a keen eye for innovative, a deep logistical understanding and utilizing technological solutions in a manner that benefits the business best.

In our nearly 40 years of business, here are the current top four methods for reducing costs and increasing profits in the warehouse.

1. The Power of CAD

Get the most from your warehouse – down to the last inch with engineering and design professionals. If you are working with a warehouse solution professional, they should know how to listen to your particular operation challenges to find solutions customized to your application. If they cannot, that’s a clear warning sign.

By using CAD, you will learn ways to improve the flow – and therefore the efficiency – of your operations. Along with this specific information, there are numerous and varied tools to help you get better organized and make the most of your warehouse and distribution center.

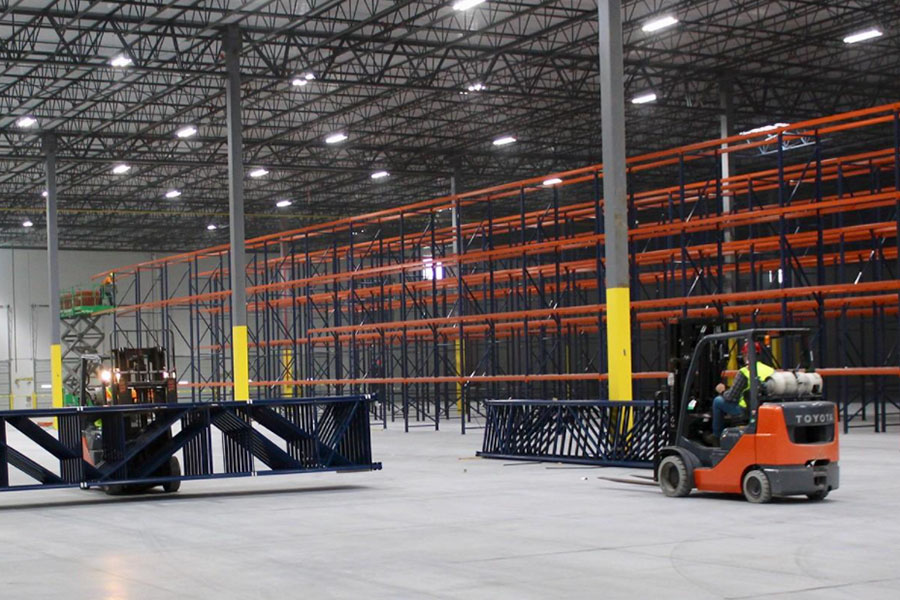

2. Warehouse Storage Systems

The right storage system should click with your business, making it easier and more convenient to get work done. The wrong storage system simply adds on superficial layers of faux organization that fail to become part of the warehouse culture.

At the most basic level, using the correct pallet racking system, conveying and shelving can make a big difference in how easily your operators can pick and place product while keeping an eye on the value of your products.

Would a first-in, first-out (FIFO) system work better for you?

For some, it’s first-in, last-out (FILO) that makes the most sense.

Do you have enough going on to need to be able to pick and place from both sides of your pallet racking? Are some of your products of varying shapes and sizes? All of these, and more, are considerations that need to be taken into account when selecting the pallet racking, conveying and shelving systems that will best suit you.

3. Optimize Aisle Width

Do you know how wide your aisles should be for optimal usage? Without this magic number, you may be wasting valuable space that could be making you money.

It’s simple – removing wasted space allows you to increase the number of aisle, which is directly related to the number of pallet racks your warehouse can support. A professional assessment can reduce wasted space and increase the amount of pallet racking by up to 60%. When you are considering changing your warehouse, ask your salesman to do a space analysis. It’s even better to request a CAD drawing.

4. Automation and Robotics

Make technology your hardest working employee hands down.

Learning how to integrate automation and robotics is fast becoming the norm for material handling warehouses and distribution centers. As more and more companies start to see the benefits of integrating automation into their operations, those who don’t will be left behind on the productivity and efficiency scale.

There are several reasons why moving towards automation and robotics makes sense, including:

- A transitioning workforce – with labor shortages and less manpower to replace those retiring, moving towards automation and robotics means you can put your human labor into more valuable positions in your organization.

- More hours worked – Automation and robotics don’t need holidays off, sick days and overtime pay.

- Increased safety – Using robotics and automation not only increases productivity, it also decreases injuries from handling heavy product.

- Easy integration – More and more software and products are being developed every day that make integrating automation and robotics into your IT system easier.

Having confidence in your warehouse organization is the first step toward decreasing waste and product handling time. As markets continue to tighten, the difference made by being able to add an extra aisle or cutting production time through automation can significantly impact your bottom line.

At Shoppa’s Material Handling, we can help you design and integrate a warehouse system that will give you a superior ROI, while maximizing your operations.

Contact us today to find your unique material handling warehouse solutions.

Pallet Rack 101

When opening a new warehouse many owners feel limited by the space they have. In a fast paced work environment the accessibility to your product is limited greatly by the space provided. In order to open up the work space, warehouse racking is used to stack pallets of products vertically and horizontally. The many advantages pallet rack systems provide are utilization of space, safety, durability, accessibility, and convenience. When considering pallet rack it is important to know what options are available for you and what specific style of racking is best for your business.

Storage Rack

This is by far the most multipurpose use of rack and most common. Storage rack allows your pallets to be accessible from the front and back and can be configured in many varieties. Wire decks are typically used with this system, which help prevent the pallet from falling through the rack. Set up is simple, and can be done quickly.

Flow Rack

This type of rack is used mostly with perishable or time sensitive products. The rack lanes are slanted allowing pallets to slide forward on rollers as the front pallet is removed, making it a first in first out storage system.

Drive-in Rack

Primarily used for high density storage. This system allows a forklift operator the ability to drive into the rack to lift out heavier pallets. This style of rack maximizes the warehouse space available. Similar to storage rack, drive-in can be configured to use first-in/first-out or last-in/first-out storage system.

Cantilever

This type of rack is primarily used for long bundled items. The system allows there to be multiple arrangements to hold many different sized items at once. The rack system can be one sided where it is normally positioned against a wall or double sided as long as there is enough clearance. Cantilever is commonly used to hold lumber, plumbing supplies, pipes and steel rods.

The many options and legal restrictions that must be considered when purchasing racking can be overwhelming. Shoppa’s Material Handling has a team of professionals who design these systems every day and can work with you to meet your storage needs and keep the work space safe. Shoppa’s offers free CAD design layouts to suit your space perfectly. Feel free to contact us today for your customized design layout.